Newsletter Subscription

Enter your email and we will send you more information

AREX+ 250 Horizontal is a mechanical ventilation device with dual airflow and heat recovery for ceiling installation. The device, with good performance, is designed to provide the necessary air renewal rate to the environment and recover heat from the exhausted air expelled to transfer it to the fresh air introduced into the environment. The high-performance devices are built with a robust sheet metal structure.

Each unit is equipped with:

All units, compliant with European ERP directives and EN standards, are provided with CE marking and DoP.

The units are designed to perform the following functions in residential or small commercial settings:

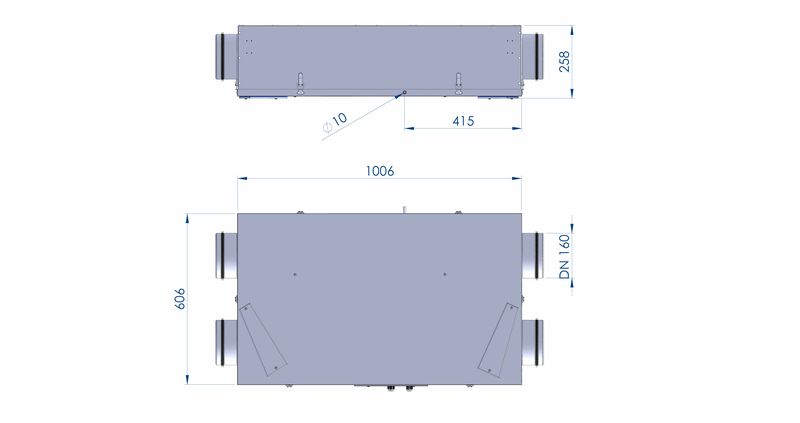

They can be installed in false ceilings to be connected to a ventilation network.

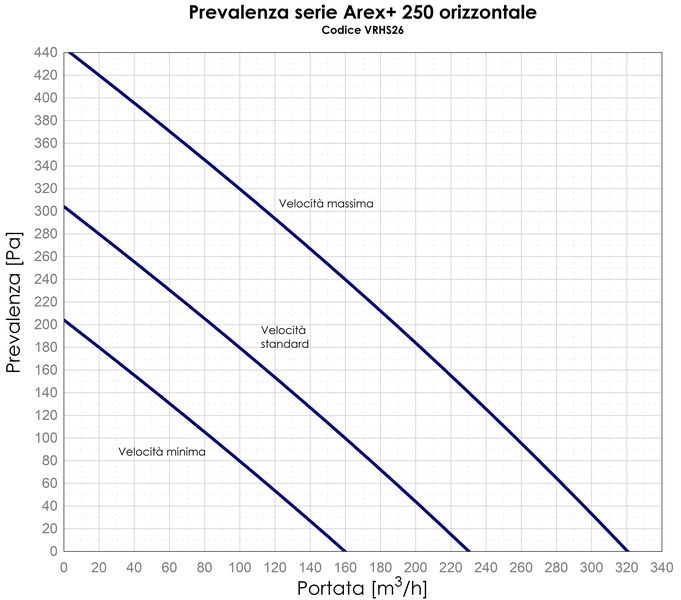

The air renewal capacity of each unit is 250 m³/h.

AREX+ 250 horizontal ensures an air renewal rate of 0.5 Volumes/h for rooms with a floor area of 150 m² (if the height is 2.80 m).

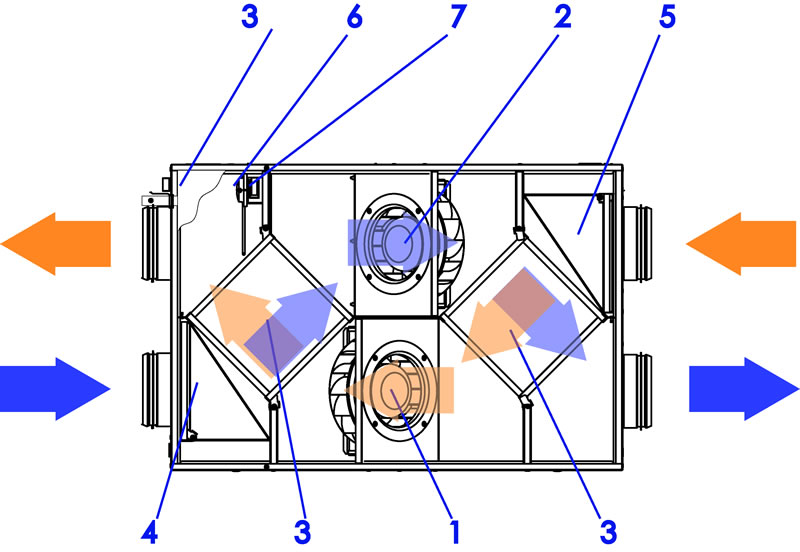

The machine is equipped with a centrifugal fan with reverse blades, with a maintenance-free motor (1), with thermal protection against overloads, which sucks in the exhausted air to send it outside. A second fan (2), with the same characteristics, sucks in fresh air from outside and sends it to the rooms. Through two exchangers, in series with each other (3), the heat contained in the exhausted air is recovered and transferred to the fresh air. The crossflow exchangers are made of aluminum. The outside air is filtered (4), as is the exhausted air extracted from the technical rooms (5). When the outside air temperature drops to the point of risking ice formation in the exchangers, the fans stop for the necessary time. A machine control unit (8) oversees proper operation. The condensate formed in the exchangers is collected in the tray (6) and sent to the drainage pipe (7).

The airflow rate can be varied according to needs, both manually and automatically. Automatic variation is possible with the installation of sensors capable of detecting odors and pollutants (optional).

| Description |

AREX+ 250 Horizontal |

|

| Code | VRHS26 | |

| Nominal Airflow Rate | m³/h | 250 |

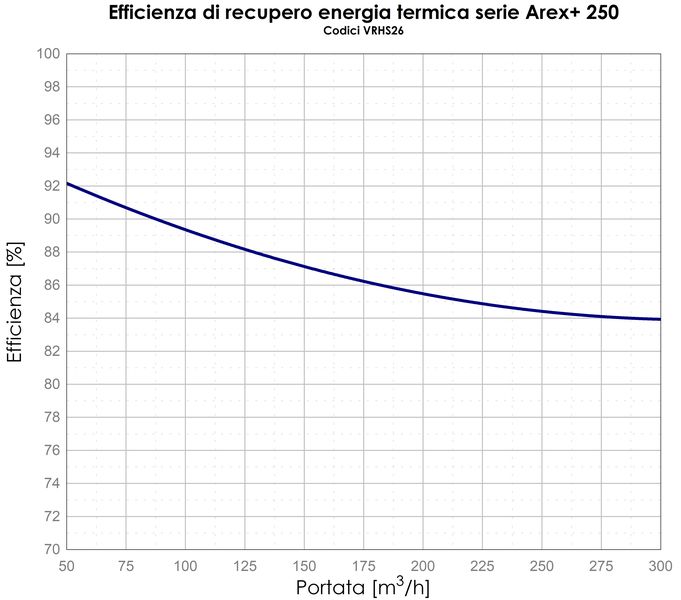

| Efficiency | % | > 90% |

| Recovered Thermal Power in Winter | W | 1580 |

| Recovered Thermal Power in Summer | W | 550 |

| Max Speed Power Consumption | W | 85 |

| Max Speed Current Consumption | A | 1.54 |

| Power Supply | V/ph/Hz | 230/1+N/50 |

| Empty Weight | kg | 29 |

| Noise Level at Max Speed | dB(A) | 53 |

Note:

The exchange efficiency and recovered power in winter are for ambient air at +20°C, 50% RH, and external air at -5°C, 80% RH. The recovered thermal power in summer is for ambient air at +26°C, 50% RH, and external air at 35°C, 70% RH.

Under different working conditions, the values obtained will vary depending on how much the operating conditions deviate from the nominal values.

Ceiling-mounted ductable air handling unit in galvanized sheet metal, with the function of air renewal and heat recovery from exhausted air for maximum energy efficiency. Air renewal flow rate 250 m³/h, counterflow heat exchanger efficiency over 90%, sound power 53 dB(A) according to UNI EN ISO 3746:1997. Built-in automatic free-cooling and clogged filter signal according to ErP 2018.

In case of ceiling installation (in a false ceiling), it is recommended to use appropriately sized fasteners and brackets, which should be connected to anti-vibration joints selected according to the type of structure to which they will be attached. It is recommended to line the inside of the false ceiling with high-density sound-absorbing material and provide one or more openings for machine extraction and subsequent cleaning of air filters, checking the refrigeration circuit, maintenance, and control of the electrical panel. Provide an opening in the false ceiling of sufficient size to disassemble and extract the machine completely.